With a single stage regulator the delivery pressure rises as inlet pressure decreases – why?

As high pressure gas enters a regulator, it pushes on the seat and the combined pressure of the high pressure gas and the valve spring closes the valve seat. A pressure adjusting device, i.e. an adjusting screw or knob, exerts downward pressure on the diaphragm and valve, opening the seat and allowing gas to pass through.

Why do cylinder valves have different thread types?

It is required in the U.S. by OSHA and the Compressed Gas Association (CGA) that cylinder valves be designed differently to prevent interchangeability with gas systems and equipment. This is one of the most important safety practices in the gas industry. For instance, if a used acetylene regulator were allowed to be assembled to a full oxygen cylinder, the result would be a catastrophic fire/explosion with the possibility of severe injuries and/or death to personnel in close proximity.

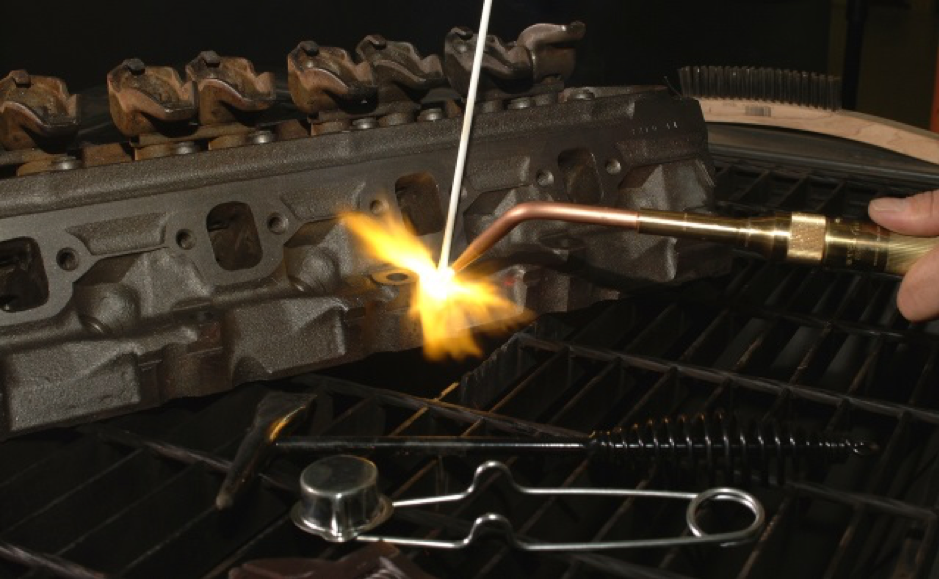

What is the difference between gas welding and braze welding?

Gas Welding

The American Welding Society defines gas welding as a group of welding processes wherein coalescence is produced by heating with a gas flame or flames, with or without the application of pressure, and with or without the usage of a filler metal. Gas welding involves the melting of a base metal and a filler metal, if used, by means of the flame produced at the tip of a welding torch. The molten metal from the plate edges and the filler metal, if used, intermix in a common molten pool and upon cooling coalesce to form one continuous piece.

Proper use of purge devices can extend the life of specialty gas equipment in corrosive gas systems

The proper use of purge devices can extend the life of your equipment by 2-3 times in corrosive gas systems. The costs associated with equipment used for corrosive and reactive gases is significant – up to $1,500 for a single regulator, or $20,000+ for a gas cabinet with all the bells and whistles.

Did you know that a protocol station can extend the life of a regulator?

Protocol stations are sometimes referred to as single station manifolds or regulator mounting stations. An ideal protocol station is a regulator mounted to a fixed bracket with an attached pigtail.